Huachen Refractory

cement Rotary kiln brick/lime kiln brick

cement Rotary kiln brick/lime kiln brick

Phone/WhatsApp

008618939512185

Email :info@hcrefractory.com

Web : www.rotarykilnbrick.com

- Home

- About us

- Product

- Silica Mullite Brick for Cement Kiln

- Magnesia alumina spinel rotary kiln brick

- Magnesia Chrome rotary kiln brick

- Magnesia alumina zirconia rotary kiln brick

- Anti Spalling High Alumina brick

- Corundum Mullite Castable for rotary kiln

- Corundum Based Castable for rotary kiln

- Steel Fiber Reinforced Castable for rotary kiln

- High Alumina Low Cement Castable

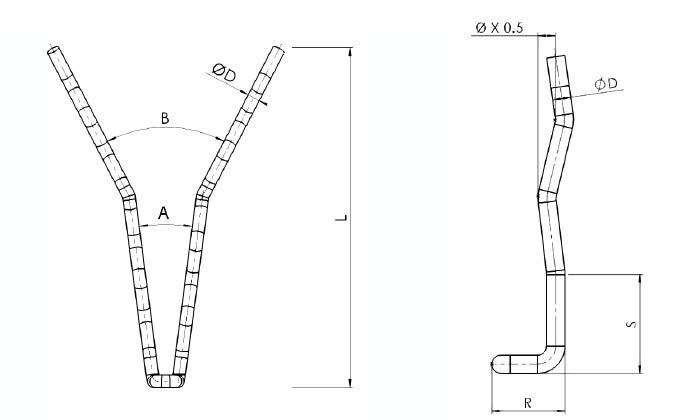

- Refractory Anchor

- News

- Support

- Contact us

- MY Enquiry

- Blog